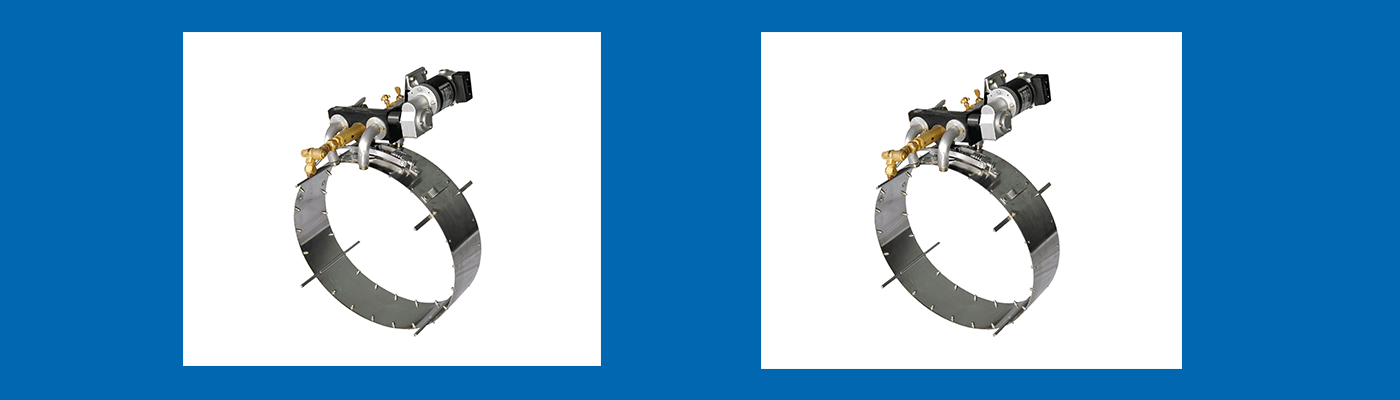

Pipe Beveling Cutting Machine (Motorized)

The Pipe Beveling Cutting Machine from SPM Equipment motorized is fast, accurate, and versatile. A single operator can position the band and beveling machine easily a few times. The Pipe Beveling Cutting Machine Motorized head is constructed of cast aluminum.

Our pipe beveling cutting crawler is lightweight, and its compact design allows for easy one-person setup and operation in Russia, USA, UAE, Australia, and Malaysia.

Pipe Beveling Cutting Machine Motorized requires a stainless steel band for pipe cutting. Each size band is required for pipe cutting. Pipe beveling cutting crawler motorized moves around the stainless steel band for cutting pipe.

These Pipe Beveling Cutting Machines are lightweight and adaptable to multiple pipe sizes.

At SPM EQUIPMENT, we take pride in our advanced technology and superior quality products. Our Pipe Beveling Cutting Machine Motorized is equipped with a powerful motor that ensures quick and precise cutting of pipes.

The machine is designed to handle various pipe sizes, making it an ideal solution for industries involved in pipeline construction equipment and maintenance. With its durable and lightweight design, our pipe cutting crawler is easy to transport and set up on job sites.

Pipe Beveling Cutting Machine - Feature & Advantages:-

- Assures accuracy.

- Design to work on all SPM stainless steel bands.

-

A motorized drive is optional.

- Mounts easily anywhere on the pipe.

- Smoothly, accurately cuts and bevel.

- Available size 16” to 64”

- Pipe Beveling Cutting Machine is adaptable to any beveling requirement.

Pipe Beveling Cutting Machine Manufacturer

The Process

SPM Equipment, a prominent manufacturer of pipe beveling cutting machines, caters to a diverse range of customers. Notably, our clientele comprises Oil and Gas Pipeline Equipments companies, construction contractors, and manufacturing facilities.

Fast and extremely precise, Wachs split frames are available in models to handle from .5 inch to 120 inches (DN25-3000) OD and can be configured to bevel, compound bevel, and create J-Preps with specific radius and precise lands.

We have meticulously designed our manufacturing process to ensure that our machines attain the highest quality standards and meet stringent criteria for precision. So, the process begins with the selection of high-quality materials. We use only the best materials in our machines, including steel, aluminum, and plastics.

After selecting the materials, our team machines them to precise tolerances, ensuring utmost accuracy. Furthermore, we equip our machines with CNC controls, ensuring precise cutting to meet exact specifications.

We meticulously execute our assembly process, taking great care to ensure precise alignment of all components. Furthermore, they undergo a rigorous testing to make sure that they meet our high standards of quality and performance.

A team of experienced quality engineers conducts inspections on the Pipe Beveling Cutting Machines. Thus, to make sure that they meet all of our requirements. Hence, we are confident that our manufacturing process ensures that our pipe beveling cutting machines are of the highest quality. In addition, we construct the machines to ensure durability, thereby offering you years of dependable service.

The key steps in our manufacturing process:

- Selection of high-quality materials

- CNC machining to precise tolerances

- Meticulous assembly

- Thorough testing

- Final inspection

We commit to delivering the highest quality pipe beveling cutting machines to our customers in the USA, UAE, Malaysia, Australia, and Russia.

Moreover, we design our manufacturing process to guarantee that our machines meet our stringent standards of quality and performance.